WE PRODUCE METAL PACKAGING MACHINERY CAN PRODUCTION LINES CAN MAKING SOLUTIONS

METPACKER designs and manufactures stand-alone machines as well as tailor-made fully automated turnkey production lines for round and irregular shaped tin cans and pails.

WE PRODUCE INNOVATION EXCELLENCE TECHNOLOGY

METPACKER designs and manufactures stand-alone machines as well as tailor-made fully automated turnkey production lines for round and irregular shaped tin cans and pails.

METPACKER - A New Player with Long-Standing Experience in the Metal Packaging Industry

METPACKER combines long-standing know-how in the metal packaging industry with a strong engineering approach to designing innovative, high-tech metal packaging machinery.

We are a reliable and competent partner for manufacturers seeking efficient and sustainable metal packaging solutions.

Metal Packaging Machinery & Can Production Lines

WE PRODUCE HIGH TECHNOLOGY QUALITY TAILOR-MADE SOLUTIONS

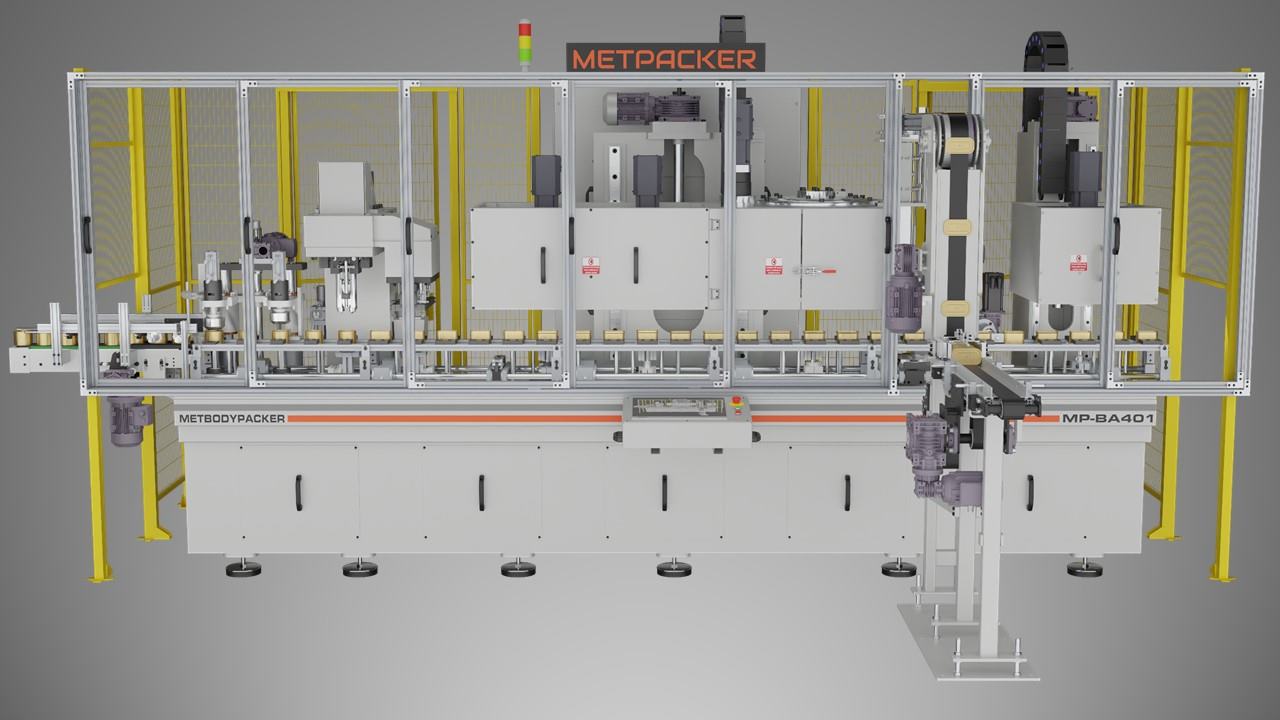

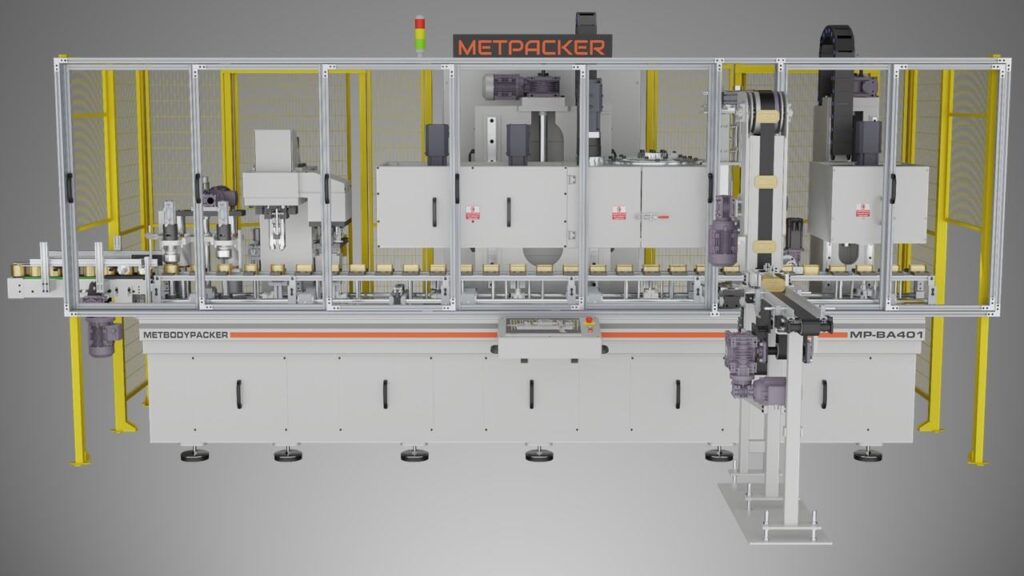

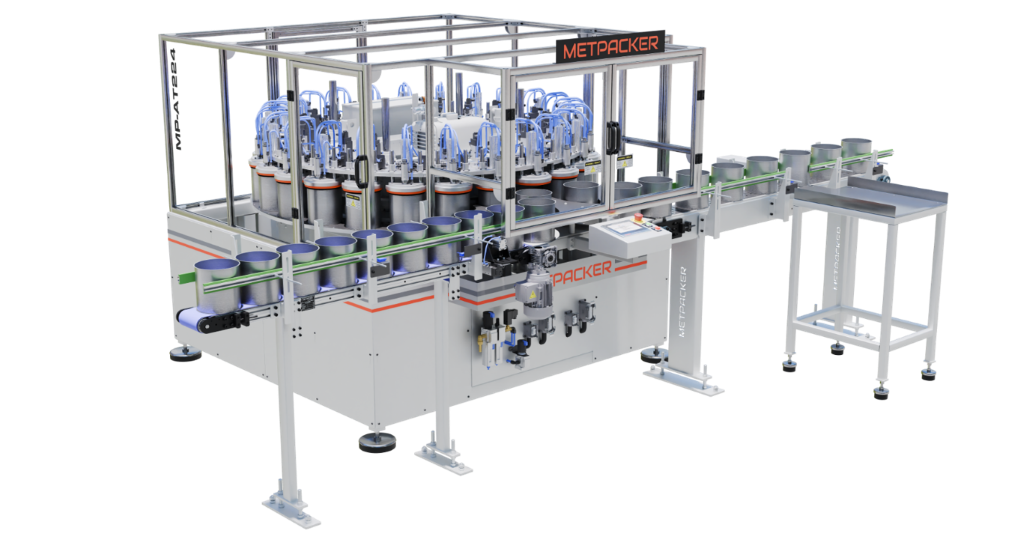

Can Body Welder

The fully automatic Can Body Welder is designed to form body blanks into precise cylindrical shapes and perform high-quality side seam welding for three-piece can bodies.

Production capacity: up to 120 cans per minute

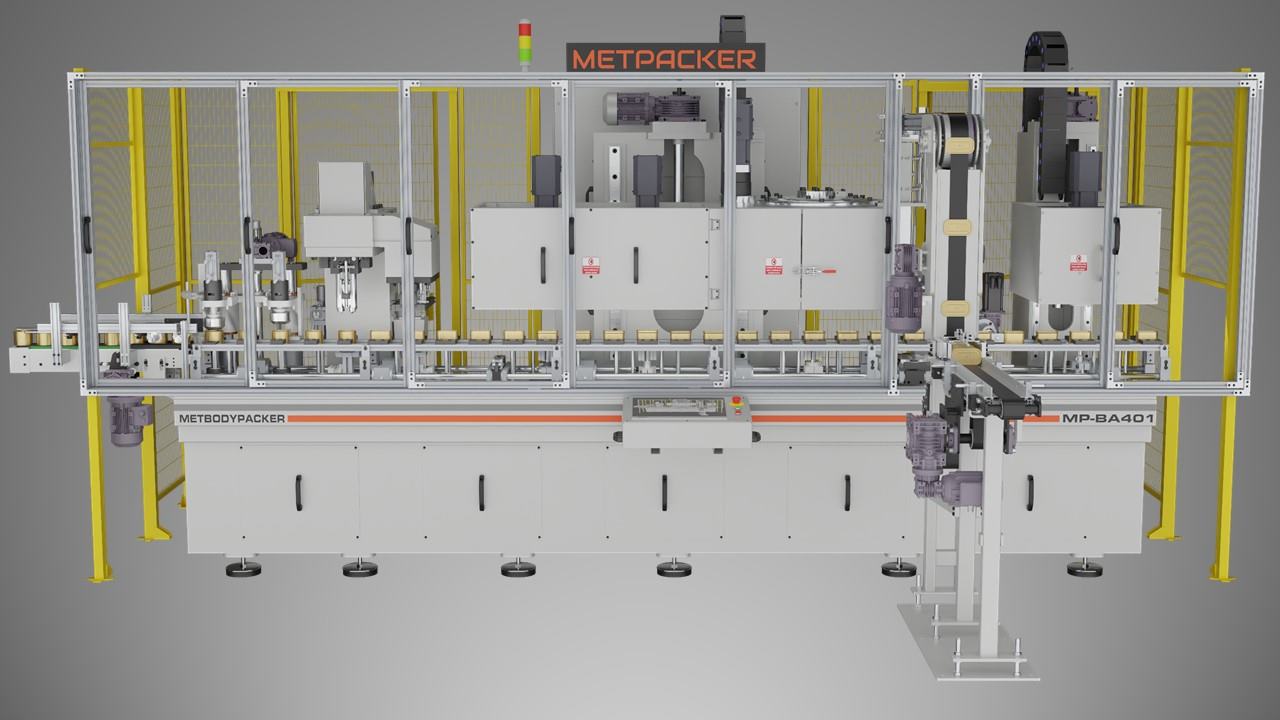

Can Body Assembly Line for Irregular Cans

Fully automatic and compact assembly line with a modular design for the production of irregular cans.

Suitable for open-top, two-side seamed, straight or conical can bodies, with customized configurations available upon request.

Production capacity: up to 80 cans per minute

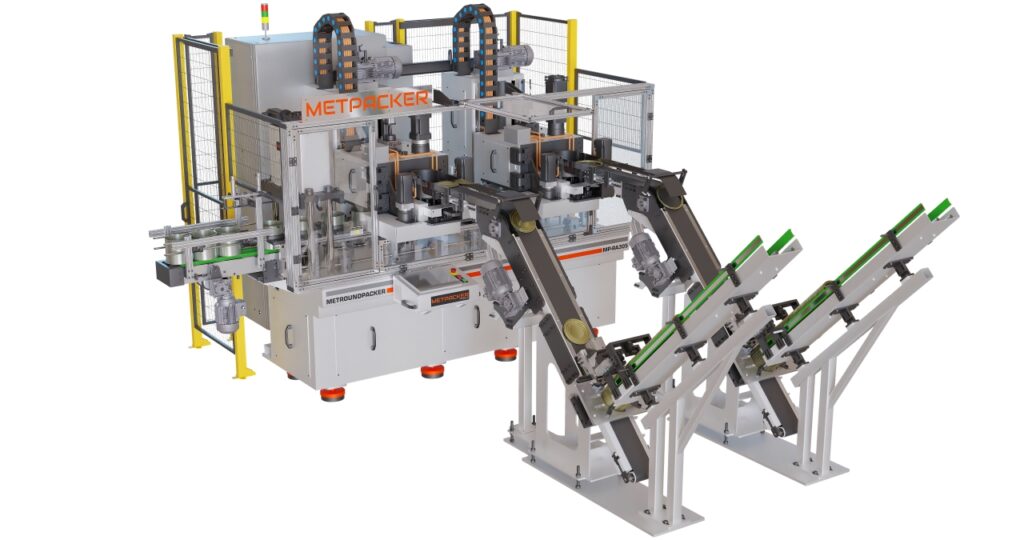

Can Body Assembly Line for Round Cans

The Can Body Assembly Line for Round Cans (METROUNDPACKER) is designed to form and assemble round can bodies in a single, integrated system.

It performs multiple operations such as flanging, top and bottom seaming, beading for food cans, expanding for pails and necking, ensuring flexible and efficient production.

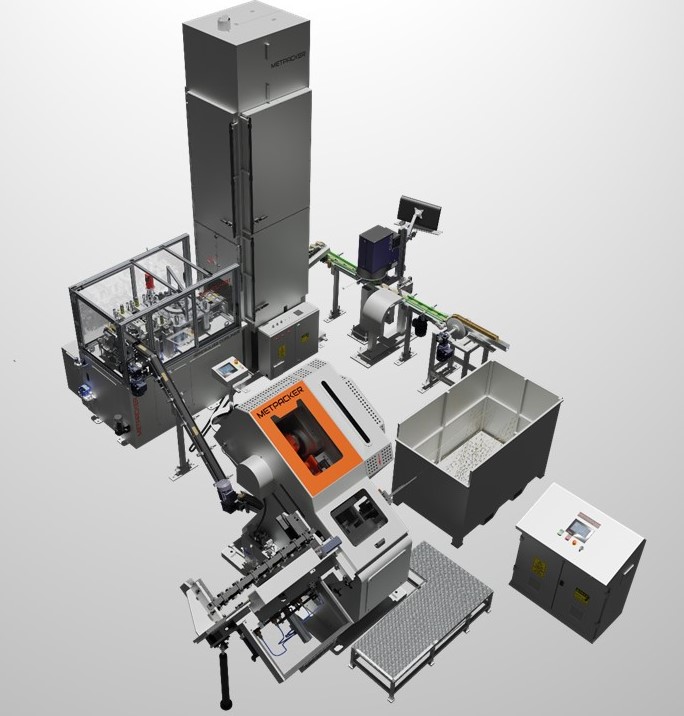

Irregular Can End Making Line

- Strip feed press with servo strip positioning

- Pre-curling and final full curling operations with die system

- Irregular end compound lining by nozzle or showerhead system

- Oven options: Vertical type with LPG or Horizontal type with LPG or induction

- Vision Control System

- Lid stacker and Wrapping system

Handle Clip Spot Welding Machine

Handle Clip Spot Welding Machine (METSPOT) is designed for spot welding metal or plastic handle clips onto the top ends of irregular-shaped or round tin cans.

Optional operations such as hole punching, edge curling and other processes can be integrated into the machine upon request.

Can Vacuum Tester

Tin Can Vacuum Tester Machine is designed for vacuum testing of round cans, irregular cans and conical pails to ensure product integrity and sealing quality.

• Rotary (carousel) type vacuum tester

• Vacuum testing based on pressure decay method

• Touchscreen HMI with user-friendly interface for easy operation

• Detection of defective cans such as micro holes, dented flanges, cracked flanges and cracked welds

• Each testing head equipped with an individual pressure transmitter and vacuum valve

• Easy can height adjustment via HMI

• Different can diameters supported by simply changing entrance and exit star wheels

Innovative. Excellence – Worldwide.